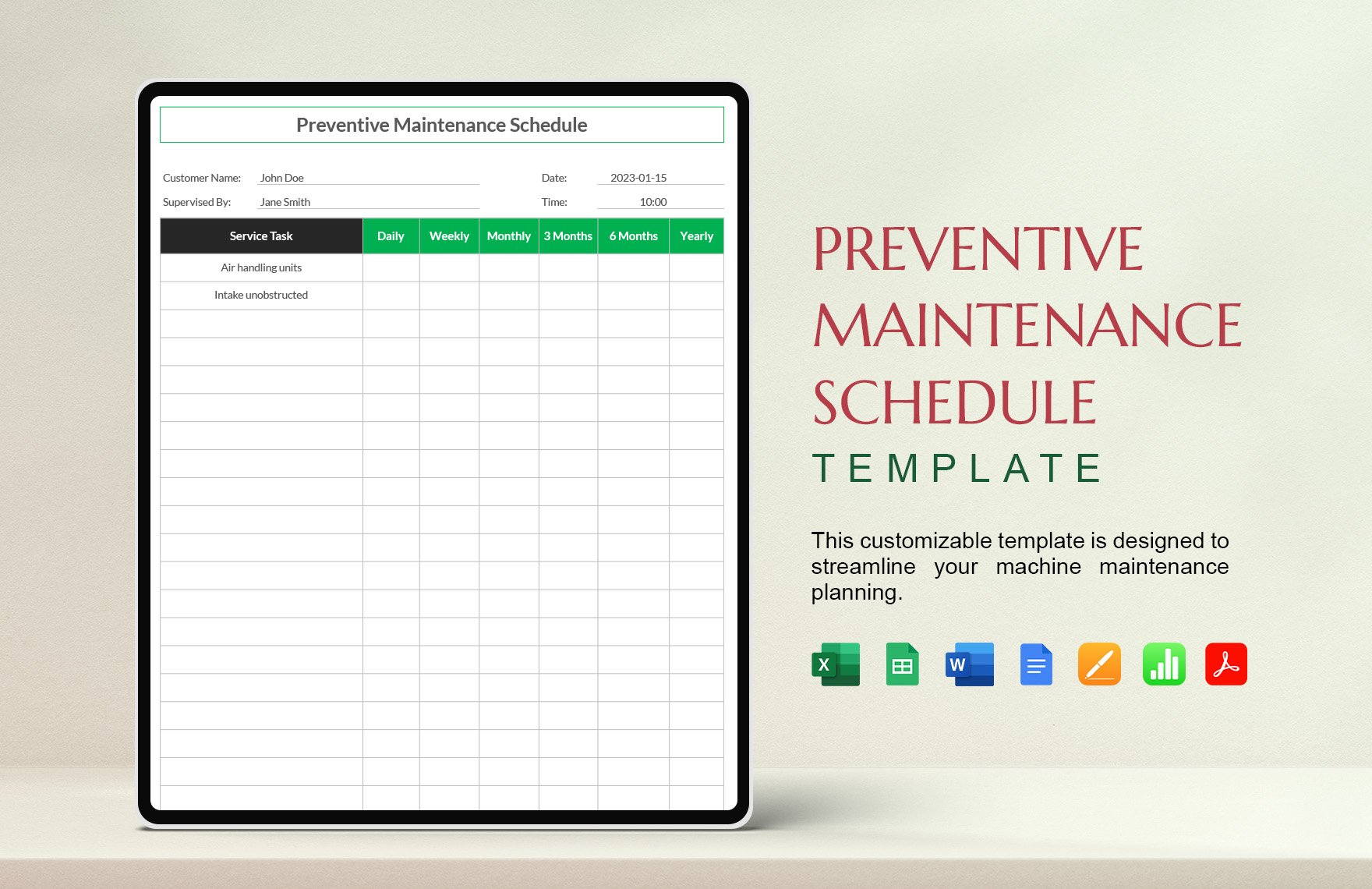

Preventive maintenance greatly helps with your business. According to statistics, a business can save up to 12-18% of their maintenance by investing to preventive maintenance instead of reactive maintenance. So, start scheduling your next preventive maintenance by downloading this comprehensive, high-quality, and professionally written Preventive Maintenance Template. This template lets you to save cost by preventing your equipment or machine to fail as you can edit and customize it. Moreover, you can have this template in Apple Pages format in any of your accessible devices. Be a responsible cost-efficient entrepreneur with our template now!

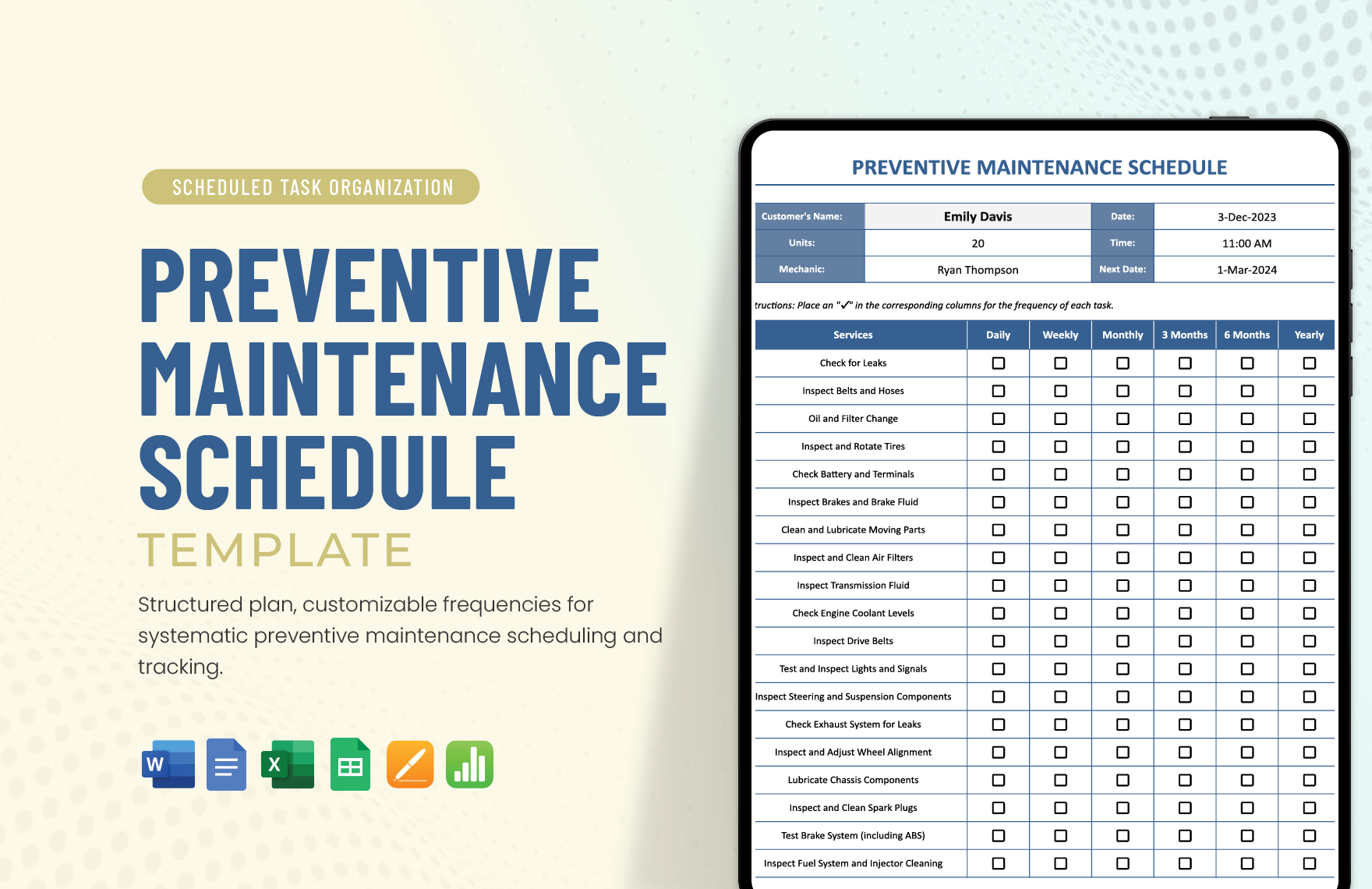

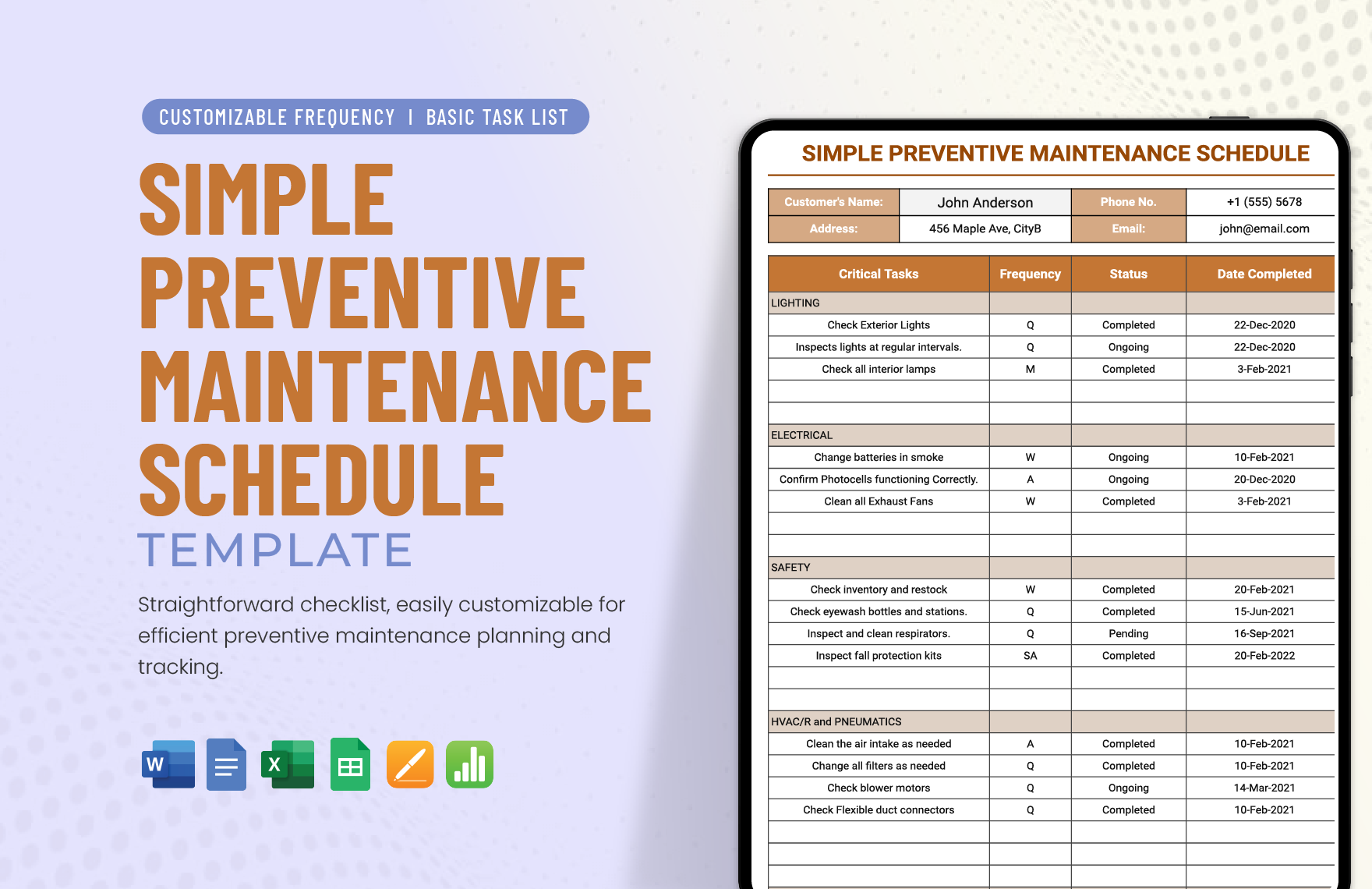

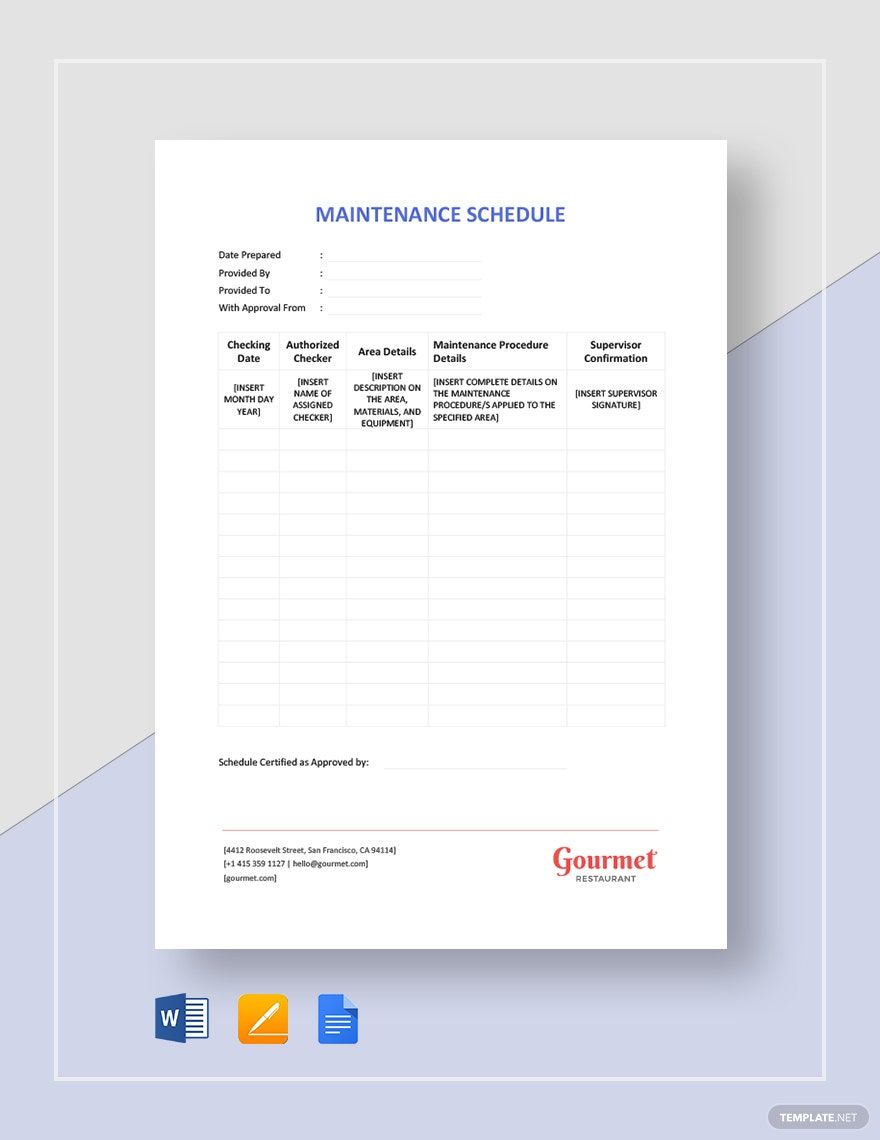

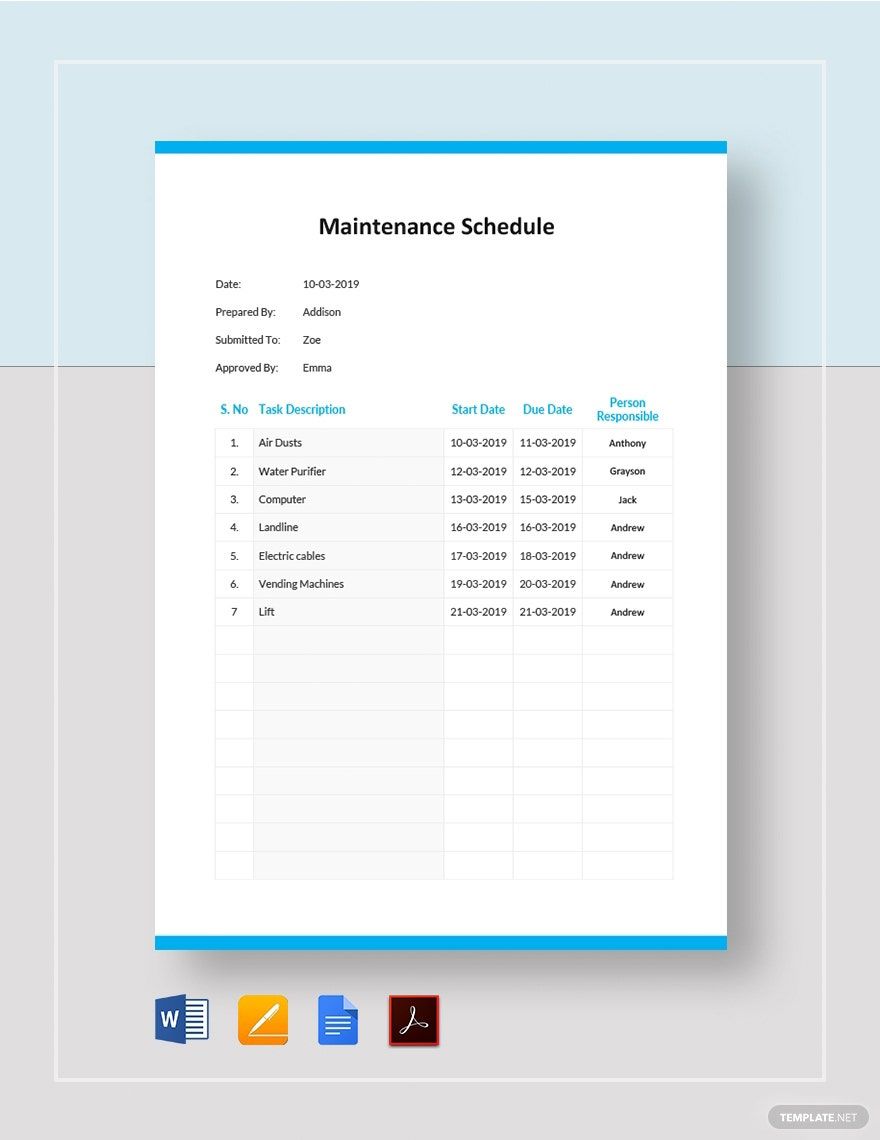

Preventive Maintenance Schedule Template in Apple Pages, Imac

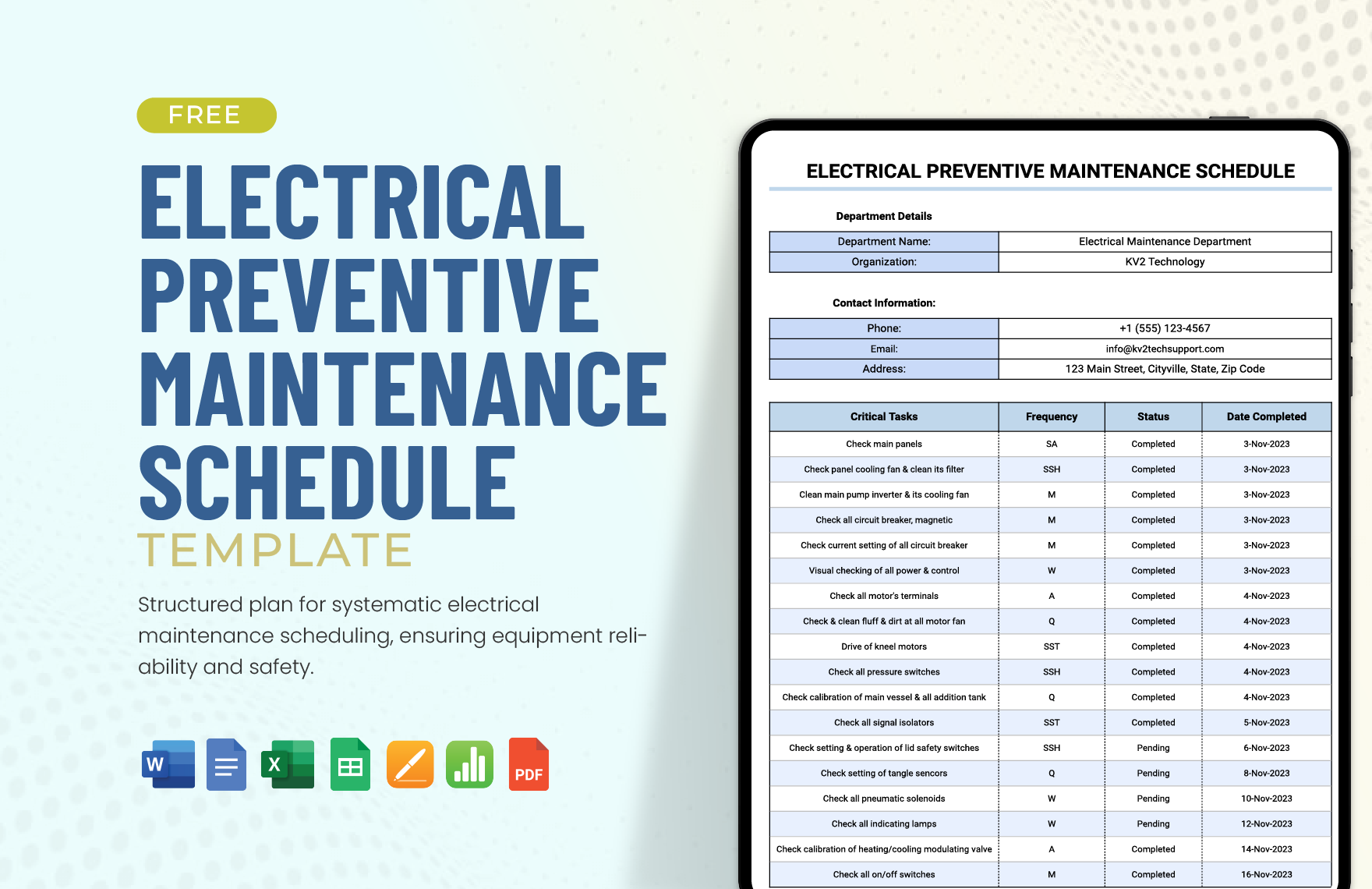

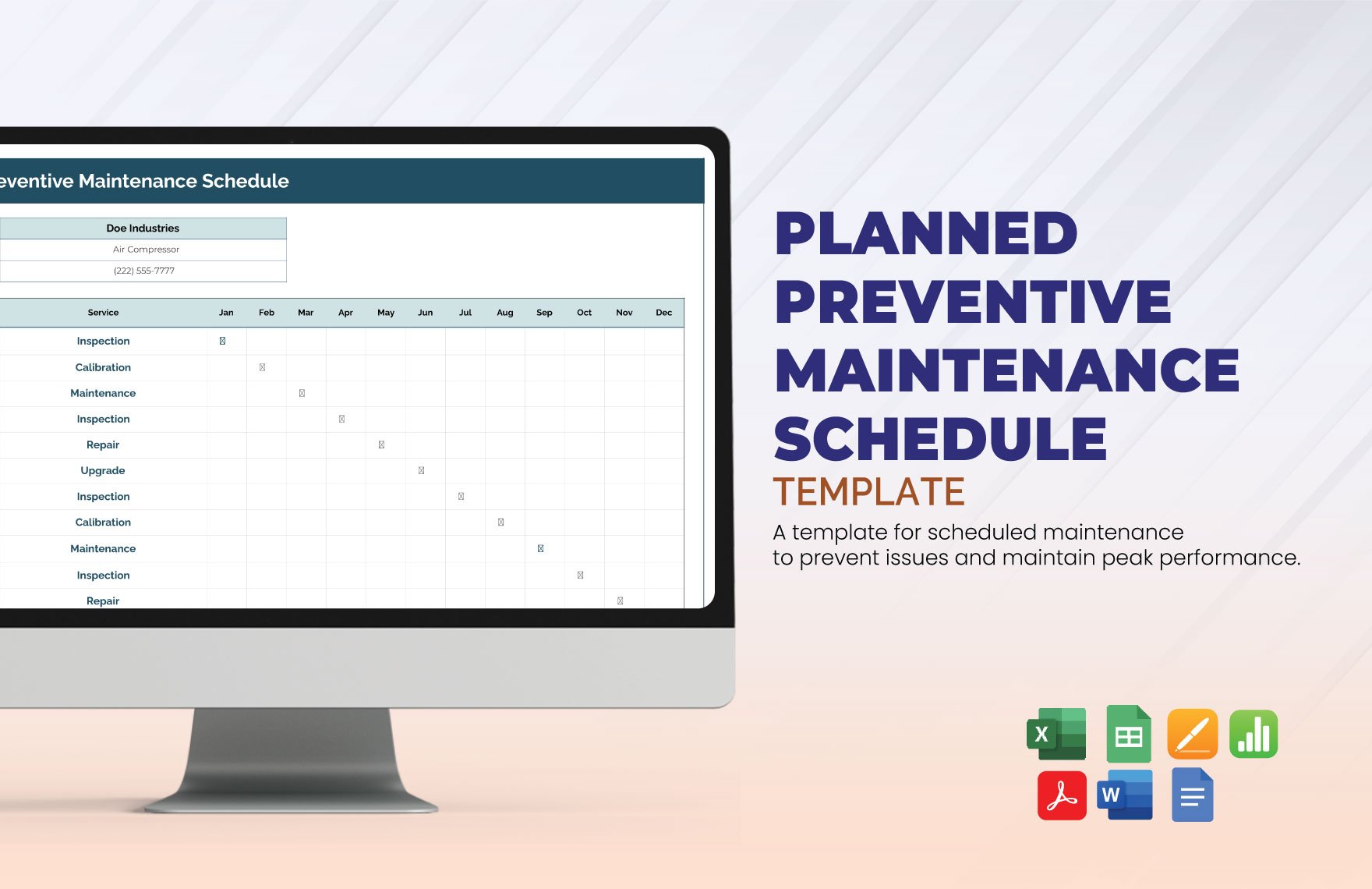

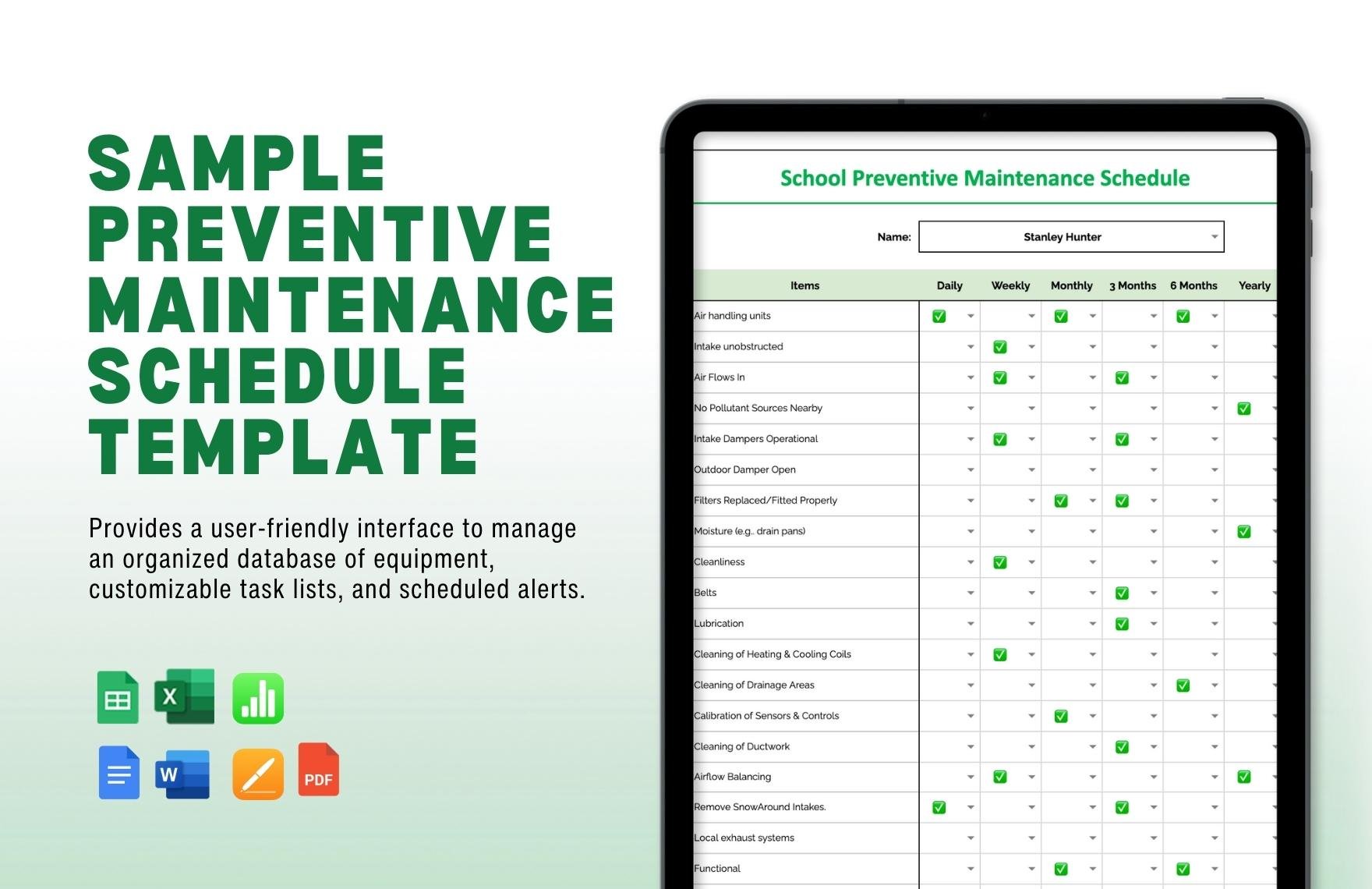

Schedule Your Preventive Maintenance Tasks by Creating the Necessary Sheets with Template.net's Free Preventive Maintenance Schedule Apple Pages Templates. We Also Have Ready-Made Equipment Maintenance Inspection Checklists and Bus Cleaning Schedules, Both of Which Are Available in Google Docs and Excel Format Too. Download a Template Now and Start Scheduling!

How to Make a Preventive Maintenance Schedule in Apple Pages

Businesses cannot prevent operation failures, especially if the equipment used are not handled appropriately. With that, you would need to come up with preventive maintenance schedule that would aid the equipment you used for daily operations. Having a schedule would remind you to conduct preventive maintenance, so you are ensured that you are guided properly. So, if you opt to make a weekly or monthly PM schedule, make sure to follow these simple tips.

1. Start with your Inventory

To start your preventive maintenance (PM) schedule, you would need to through your equipment. Make sure to have a checklist containing the machinery that you use. Usually, you need to take note about the equipment’s model, serial number, specification, asset number, category, location, department, and item cost. These pieces of information would help you in sorting them out for your schedule.

2. Conduct Equipment Analysis

Now that you are done with inventorying, you need to conduct an equipment analysis. Is the equipment working well according to its specifications? Is the equipment a high-priority asset? Keep in mind that in evaluating, no equipment would run at a 100% capacity. Evaluating these pieces of information would generate you a rational operational goal.

3. Narrate Preventive Maintenance Procedures

Once that you have come up with the list of analyzed equipment, you can now narrate its respective preventive maintenance procedures. Also, you need to decide as to how often you would conduct the procedures. For instance, if you wanted to conduct a preventive maintenance for your HVAC equipment, it would be preferable to do it monthly. But, depending on your equipment’s demand, you would need to do it often.

4. Sort the Factors of your Schedule

Collate every data that you have and start sorting everything. You would need to categorize every pieces of equipment based on its use. There is no specific format for a schedule but it is preferable to sort them by having main specifications that would introduce the sub-specifications. Then, plan the respective time period of each pieces of equipment according to its needed preventive procedures.

5. Test your Schedule

To make sure that you have generated an effective schedule, you need to test it out. Conduct test run for your equipment using the schedule. Observe the process carefully and point out as to what factor your schedule excelled and not. This would be your guide in revising it.

Frequently Asked Questions

What are the types of maintenance?

There are several types of maintenance that you can conduct, depending on your needs. You can conduct a:

1. Corrective Maintenance

2. Preventive Maintenance

3. Risk-Based Maintenance

4. Condition-Based Maintenance

What is the meaning of HVAC?

HVAC stands for heating, ventilation, and air conditioning. It refers to the systems, machines, and technologies used for indoor setting.

What is the difference between maintenance and repair?

These words are often confused and interchanged, but they have significant differences. Maintenance is the equipment service that you conduct to ensure its longevity. Repair is the service that you conduct if equipment fails to function, or even replaced.

What are other types of schedules?

1. Capacity Schedule

2. Resource Schedule

3. Service Schedule