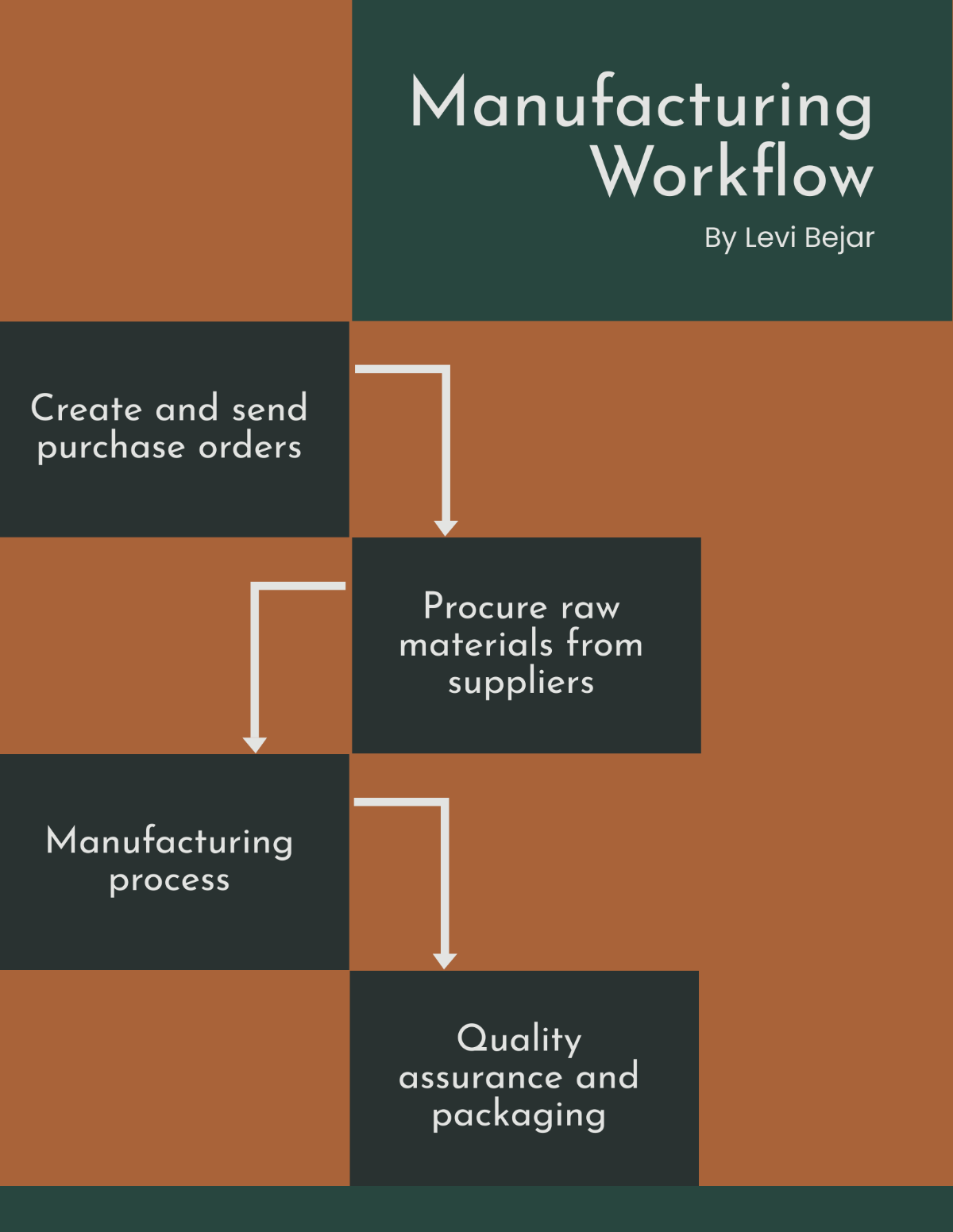

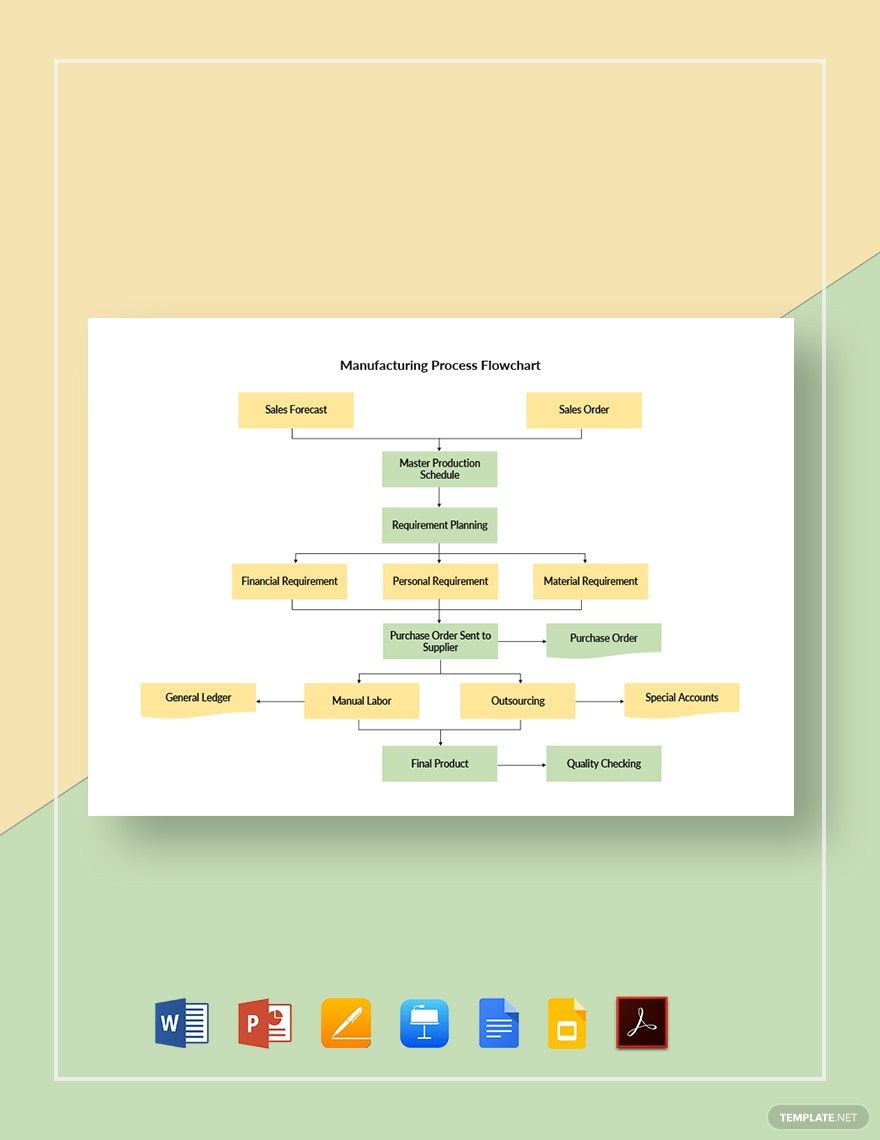

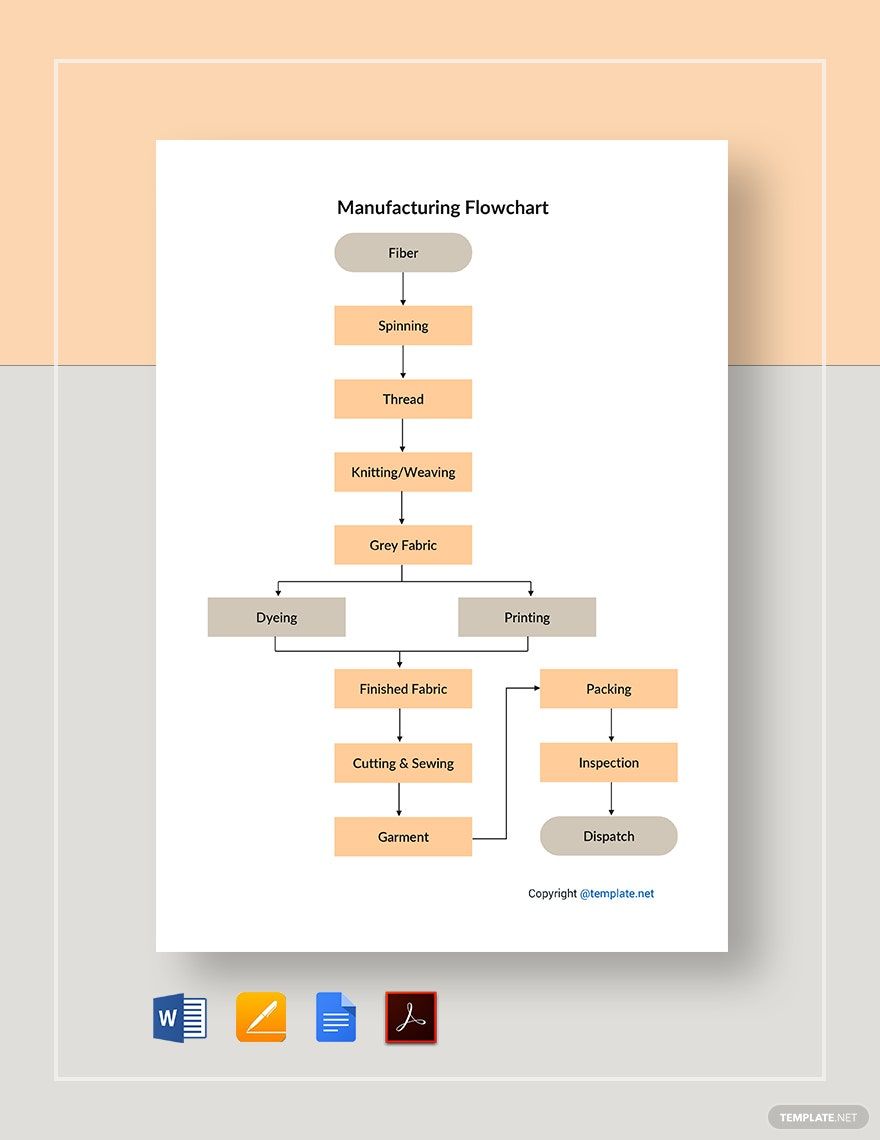

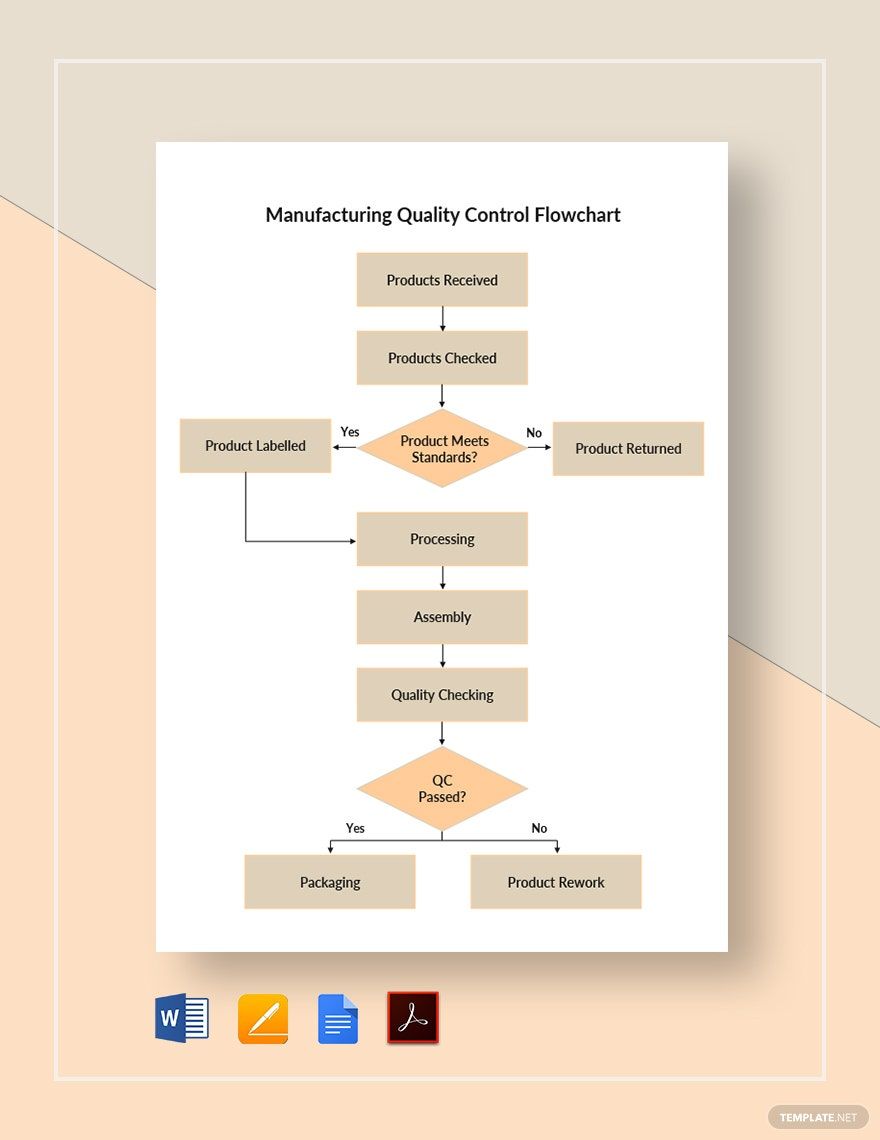

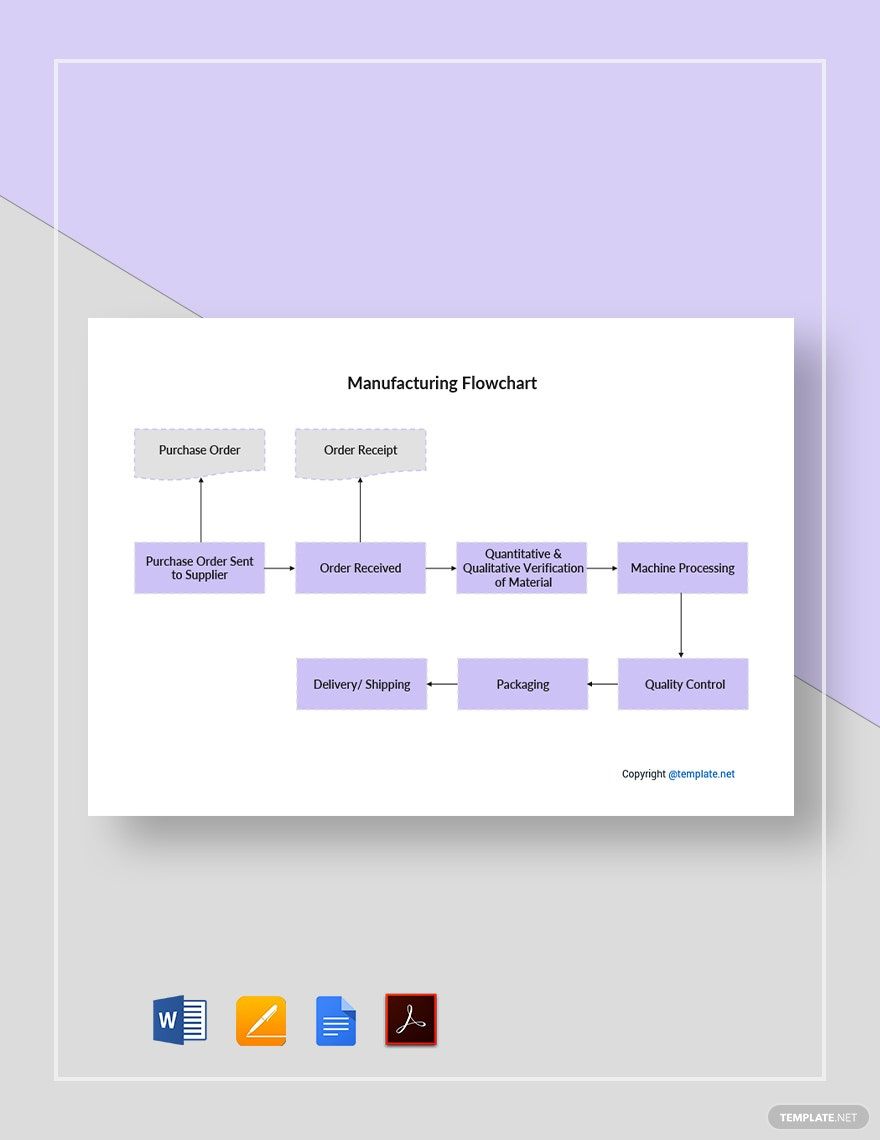

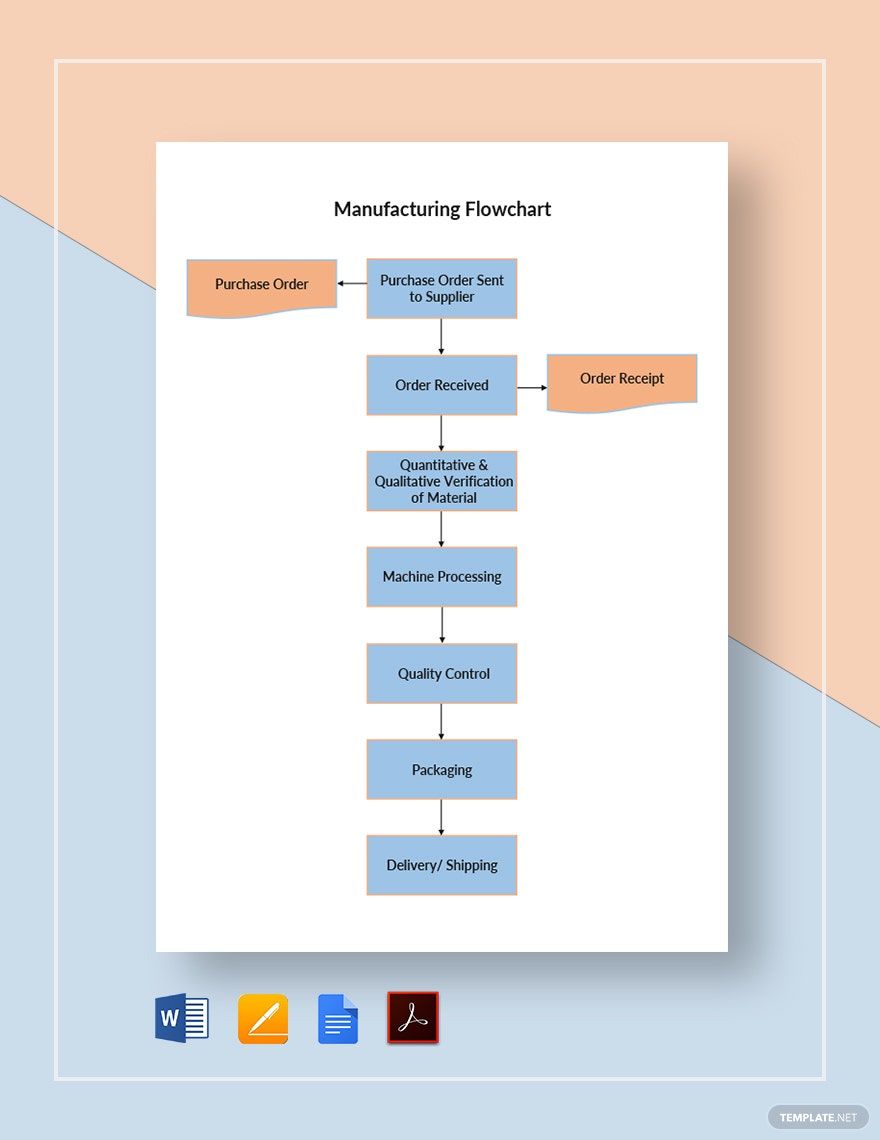

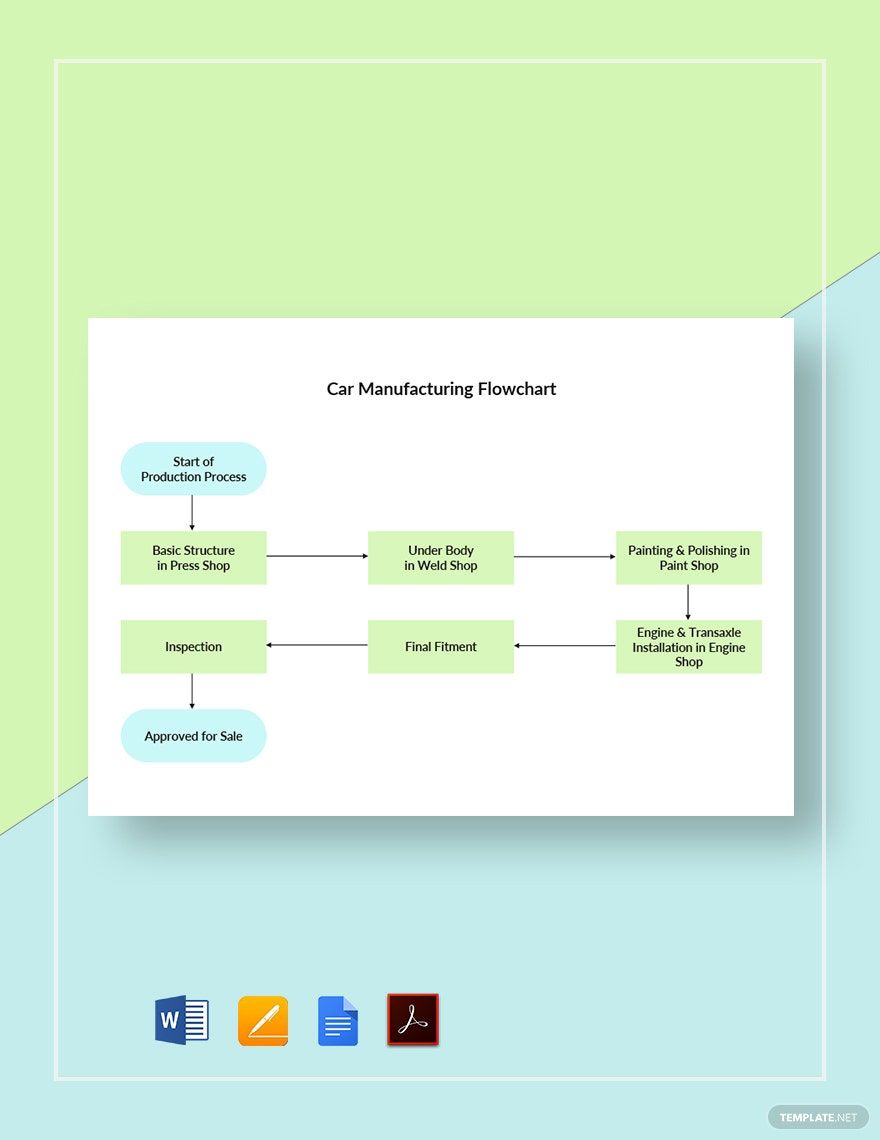

Any industrial production is composed of a series of processes that follows a stringent order. The quality of the results rely on how efficient and reliable these processes are. To ensure that the manufacturing of goods and products is optimized, you need to have clear processes. These Manufacturing Flowchart Templates feature ready-made layouts you can use to outline the manufacturing processes of your own company. Each one is professionally created, with sample content you can use as reference. These templates are available in multiple file formats, and are 100% customizable. Check them out!

FREE Manufacturing Flowcharts Templates

Give Your Business a Clear Flow and Organization When You Utilize Template.net's Free Manufacturing Flowchart Templates! We Mainly Offer Templates For Your Business and Personal Needs Such as Business Flowchart Templates, Payment Flowchart Templates, Production Goods Flowchart Templates, Application Flowchart Templates,Transaction Flowchart Templates, and Database Flowchart Templates. Download Now.

- Design

- Design Agency

- Design Agreement

- Design Background

- Design Banner

- Design Brief

- Design Brochure

- Design Card

- Design Chart

- Design Clipart

- Design Coloring

- Design Company

- Design Company Brochure

- Design Drawing

- Design Engineer

- Design Engineer Resume

- Design Firm/Company Organizational Chart

- Design Flowchart

- Design Gantt Chart

- Design Job Description

- Design Letterhead

- Design Magazine

- Design Mindmap

- Design Mood Board

- Design Page

- Design Plan

- Design Portfolio

- Design Proposal

- Design Quotation

- Design Rollup Banner

- Design Studio

- Design Vector

- Design Website

- Designer

- Designer Business Card

- Designer Cover Letter

- Designer Fashion Sale

- Designer Letter

- Designer Post

- Designer Resume

- AD Design

- Agenda Design

- Banner Design

- Billboard Design

- Bookmark Design

- Brochure Design

- Calendar Design

- Card Design

- Catalog Design

- Certificate Design

- Chart Design

- Children Design

- Cookbook Design

- Coupon Design

- D-Day Design

- Dashboard Design

- Datasheet Design

- Email AD Design

- Email Design

- Email Newsletter Design

- Envelope Design

- Father's Day Design

- Flyer Design

- Form Design

- Graphic Design Letterhead

- Graphic Design Proposal

- Graphic Design Quotation

- Graphic Designer

- Graphic Designer Cover Letter

- Graphic Designer CV

- Graphic Designer Letter

- Graphic Designer Resume

- Handbook Design

- ID Card Design

- Illustration Design

- Invitation Design

- Invoice Design

- Itinerary Design

- Label Design

- Leaflet Design

- Letter Design

- Letterhead Design

- Logo Design

- Logo Designer

- Lookbook Design

- Magazine Design

- Menu Design

- Mother's Day Design

- Newsletter Design

- Newspaper Design

- Non-Profit Design

- Nowruz Design

- Pamphlet Design

- Planner Design

- Postcard Design

- Poster Design

- Presentation Design

- Rack Card Design

- Receipt Design

- Report Design

- Resume Design

- Roadmap Design

- Schedule Design

- Sister's Day Design

- Survey Design

- Tag Design

- Ticket Design

- Timeline Design

- V-E Day Design

- Veterans Day Design

- Voucher Design

How to Make a Manufacturing Flowchart

An article by ThomasNet published in March 2020 implored companies in the manufacturing industry to start looking into modern production systems if they don’t wish to be felt behind by the growing business world. To ensure that your company, along with its products and services, remain relevant in this new, digital era, you have to start investing in research and development to optimize your operations.

For the manufacturing side of your business, you can begin by outlining the steps in the current processes your company implements. Below are the steps you can follow in making a manufacturing flowchart.

1. Identify the Process

A flowchart has to be specific. Since there are different parts to an overall manufacturing system, you have to determine which process you want to put into a flowchart. You are encouraged to choose specific processes, so you can better outline the basic and concrete steps that make up the whole production.

2. Make an Outline

Before you start working on the actual chart, put into paper a rough outline of the sequence involved in the process you’ve chosen. Carefully enumerate the steps and make sure you don’t miss any component. Preparing an outline before making the flowchart allows you to change and reorder certain parts without compromising the entire document.

3. Visualize

After you’ve completed the list of steps in an outline, take the time to picture the best placement for each one. This is the part where you begin plotting the look of your diagram. It is important that you visualize how you present the steps, as the purpose of a flowchart is to make the process easy to understand.

4. Add Supplementary Details

Once you have the final look of the flowchart, begin putting additional information to the steps you’ve outlined. These details can be symbols or simple codes that will help elaborate each part. Text and graphics go hand in hand in making your flowchart informative and presentable, so colors and other designs can highlight important details.

5. Consult and Evaluate

Don’t forget to coordinate with other personnel who are involved with the manufacturing process outlined in the flowchart. You can distribute survey questionnaires or consult with some of your team members to ensure that the details of the flowchart are correct and as specific as you can make them. The flowchart will be a guide to those who will be involved in the process, so everyone must be on the same page when it comes to all aspects of it.

Frequently Asked Questions

What is a manufacturing process flowchart?

It is a diagram of the individual steps that comprise a manufacturing process. It outlines these steps in a sequential order, and presents the details in a visually-appealing and understandable layout.

What are the different steps in a manufacturing process?

1. Concept making

2. Research and development

3. Logistics

4. Production

5. Distribution

What is the difference between manufacturing and production?

Both manufacturing and production talk about the conversion of raw materials into finished products, but the former involves the use of machinery and other resources while the latter talks about the general process of making said products.

What is optimization in manufacturing?

Optimization in manufacturing pertains to the use of the best processes to carry out the manufacturing operations. This involves steps that save time and resources to produce the same quality of products.

How can a manufacturing process be optimized?

1. Evaluate the current manufacturing process.

2. Fund more research and development projects.

3. Invest in equipment.

4. Provide additional training for all personnel and staff.

5. Encourage collaboration.